RQA - QUALITY Studio® - requirements and models quality analysis

A SMARTer way to improve the quality of your requirements, documents, and models.

RQA – QUALITY Studio® is a specialized product of SES ENGINEERING Studio (SES), fully devoted to Quality Analysis and Management of whatever work product produced along the System Life cycle. It can either work inside SES as a capability or as a Stand-Alone product.

Quality analysis of requirements, documents and models

RQA – QUALITY Studio® allows engineers to:

- Define quality

- Calculate quality

- Manage quality

- Report quality

for any work product accessed from any available connection in SES ENGINEERING Studio. This include requirements, documents, logical models, functional models, simulations, test cases, physical assemblies, risks, etc.

Engineering items of poor quality during the project concept and design phases lead to rework, extra costs, delays and, severe consequences if not detected.

RQA – QUALITY Studio® automates the requirements quality analysis, as well as the quality analysis of other engineering items. This minimizes the cost of quality inspections while increasing the consistency and overall quality of the projects.

Defects can be caused either by inadequate engineering decisions or by the incorrect representation of engineering information in requirements, models, etc. Automatic quality inspections will give engineers more time for better decision-making while providing means to detect and fix defects.

Natural Language Processing and Artificial Intelligence provide a semantic analysis for more accurate inspections.

Benefits of RQA – QUALITY Studio®

RQA – QUALITY Studio® has several benefits when working with requirements engineering. The most important are:

Quality

While performing the quality analysis, the tool analyzes requirements and other engineering items using the agreed-best practices and rules. You can use e.g. the INCOSE Guide to Writing Requirements, checklists, and other policies to identify defects, inconsistencies, and incomplete information.

Time

The quality inspection of requirements specifications is a task that requires several steps and that can be very time-consuming when not realized automatically.

Money

Reducing rework (and costs) caused by flaws at all levels in your system engineering items can be achieved by automating peer-reviewing and quality analysis.

Are you concerned with the success of your projects? This unique service will help you ensure it.

Features of RQA – QUALITY Studio®

The features of RQA – QUALITY Studio® make it a powerful tool for quality analysis of requirements, documents, and models.

Making the concept of quality analysis universal

RQA – QUALITY Studio® extends the quality analysis concept and covers all the engineering items generated during the systems engineering life cycle. It manages:

- Requirements for quality analysis

- Documents quality analysis, (e.g. SEMP)

- Logical models analysis (UML, SysML)

- Physical models analysis (MODELICA, Simulink, etc.)

- 3D models, test cases, FMEA tables…

Customizable quality functions

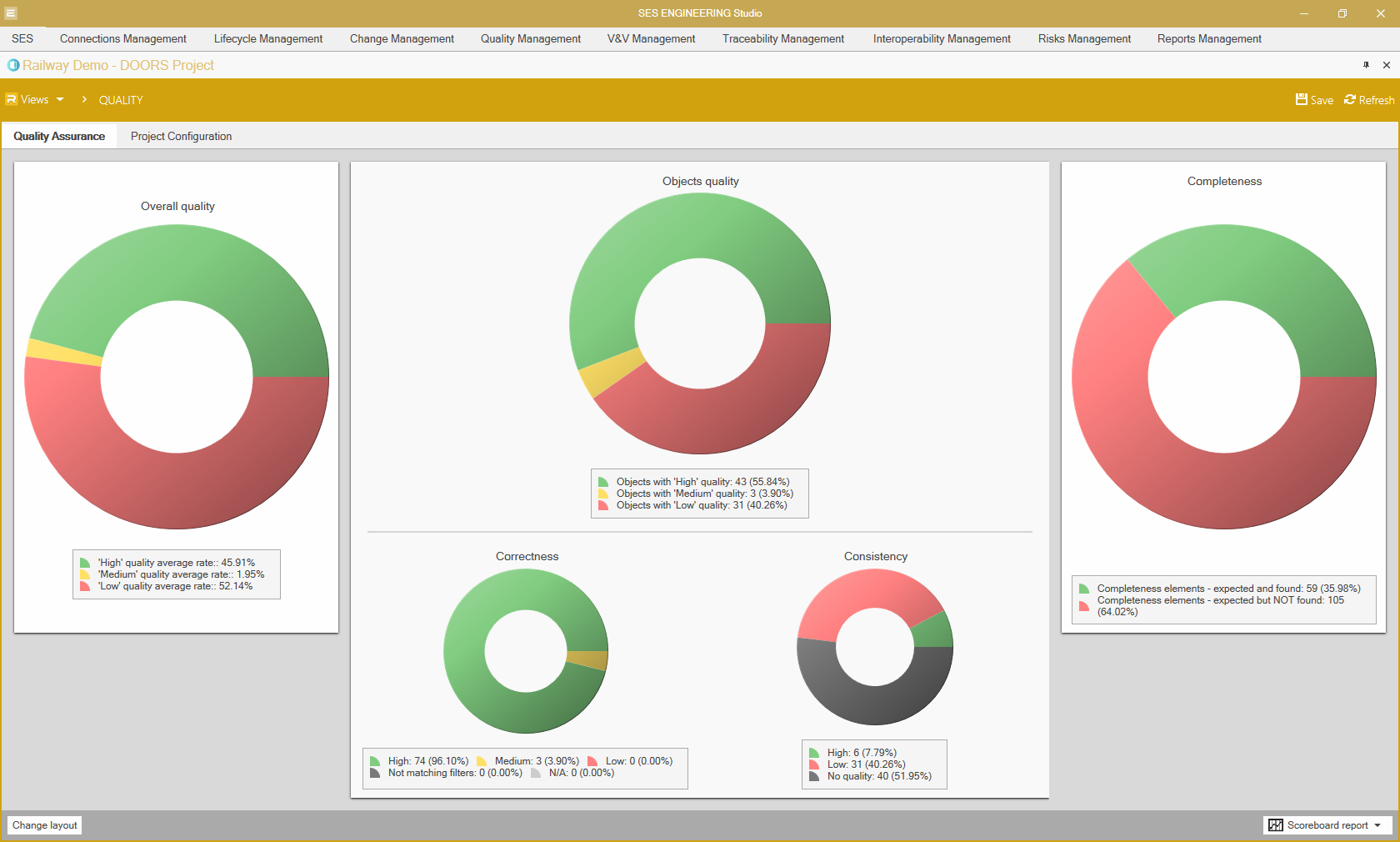

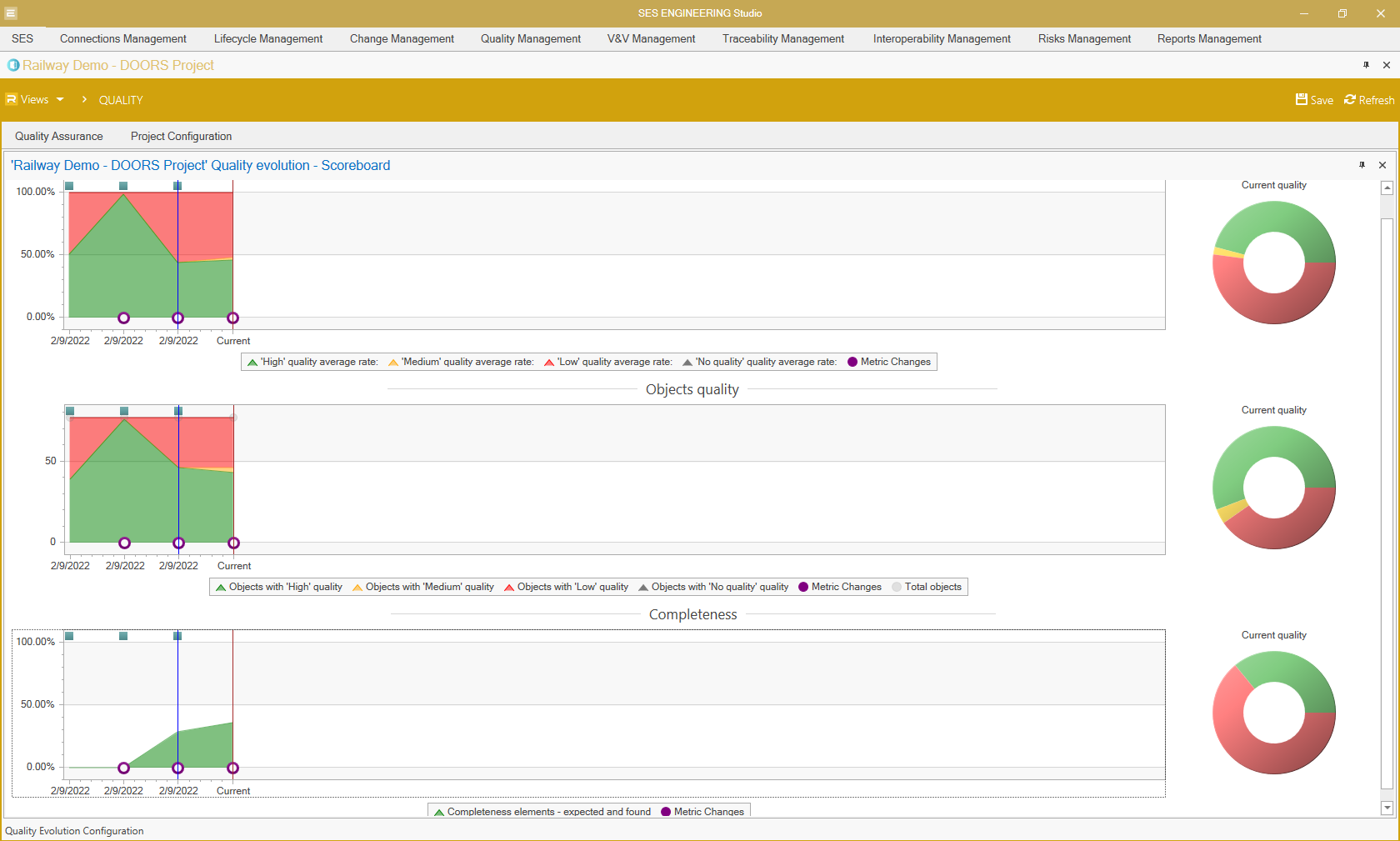

Different companies, industries, methodologies, and types of projects need different types of documents and diagrams at different levels of abstraction. RQA – QUALITY Studio® is the tool that can cope with this plethora of engineering items, methods, processes, and tools. It provides tailored analysis and configurable assessments, represented in a centralized system quality scoreboard. This way a quick understanding of the current quality status, and quality evolution of a project is provided.

Early detection of defects

Almost 90% of the defects are introduced during the Requirements Engineering and Design phases. However, only 20% of these defects are discovered.

RQA – QUALITY Studio® helps reduce the defect rate by enabling a thorough and early detection of issues in requirements specifications and logical models. Through the automatic quality analysis time and costs are reduced.

The quality management capability positioning

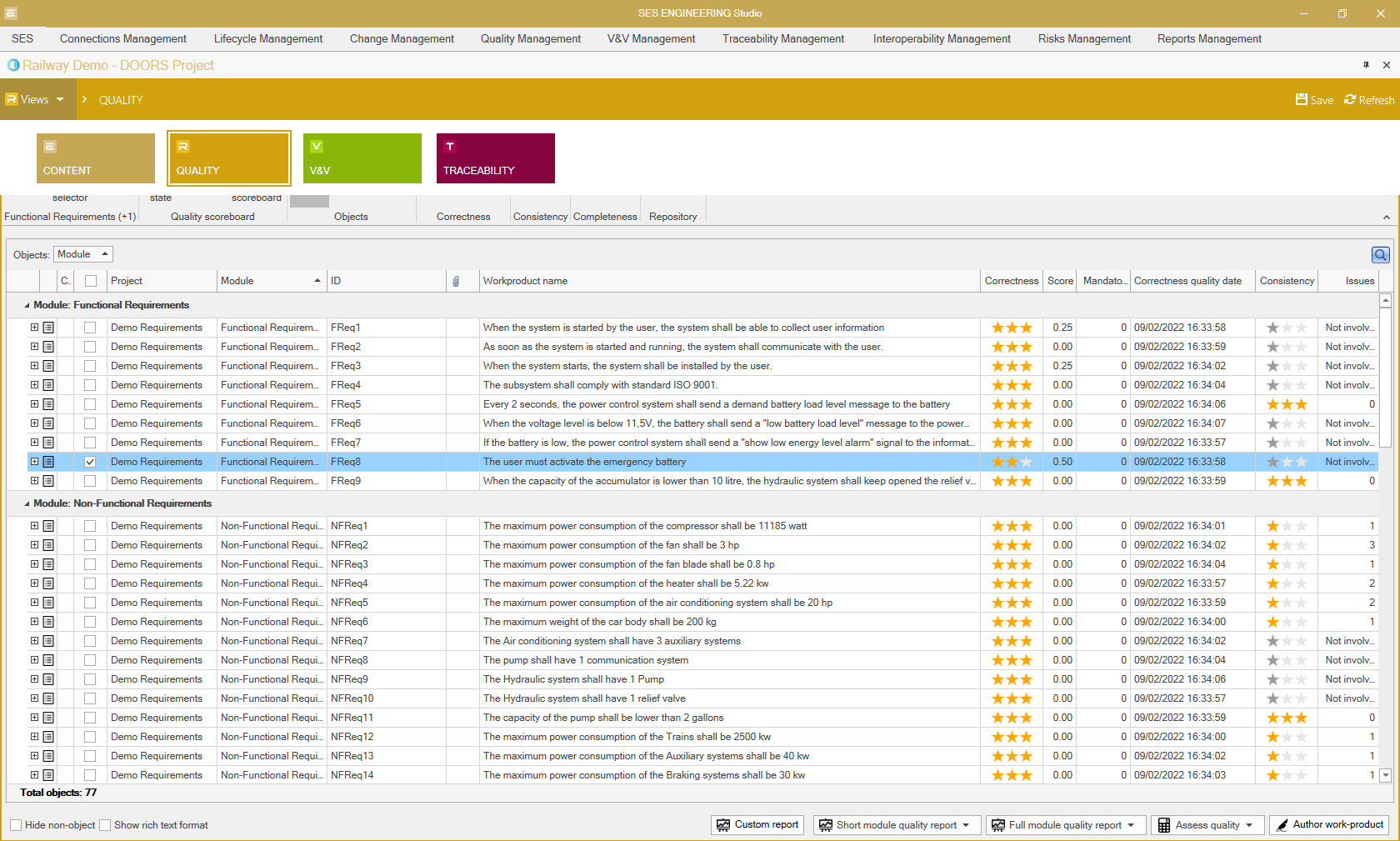

The RQA – QUALITY Studio® provides a means to connect to a large number of engineering tools (requirements management tools, UML/SysML/MBSE tools, simulation tools, MS Excel sheets, MS Word documents…). The tool accesses the key elements managed in those tools, and provides an automatic quality analysis based on the CCC criteria.

CCC – Correctness, Consistency, and Completeness– are the three quality dimensions of any engineering artifact to thoroughly analyze. While Correctness is focused on the quality of individual items, Consistency, and Completeness consider the whole requirement specification (or document or model) or set of specifications. The tool detects missing elements, as well as the lack of consistency among them.

Requirements quality analysis

RQA – QUALITY Studio® provides an extensive set of quality metrics to analyze different types of requirements repositories. It connects to IBM DOORS (both 9.x and Next Generation), PTC Windchill Requirements, Siemens Polarion, Siemens Teamcenter, MS Word, MS Excel, among others.

These metrics follow the CCC approach and include extensibility and customization features that enable increasing the number of metrics. You can use parameterizable metrics (metrics that can easily be configured by the end-users), custom-code metrics (metrics that can be coded by advanced end-users), and checklist-based metrics (which enable a manual-oriented inspection).

The Concept of Quality Project

RQA – QUALITY Studio® uses the notion of Quality Project to manage the quality of large and heterogeneous sets of engineering items in a single inspection process. A Quality Project addresses the quality of a set of engineering items, allowing a proper and global quality management activity. A Quality Project, which might connect to requirements, documents, models, etc. will not only provide correctness checking but also an overall completeness and consistency check.

Since every project is different, the RQA allows a flexible mechanism to assess different elements with a different combination of quality metrics.

Quality along the Supply Chain

RQA – QUALITY Studio® allows OEMs and suppliers to share a common quality view throughout the supply chain and to have more efficient interactions. OEMs can establish a set of metrics for a quality certificate in RQA – QUALITY Studio® and share this certificate with everyone in the supply chain. After that, the OEM can receive periodic quality reports from the supplier allowing the overview of the results using a simple procedure.

Libraries

Safety-critical systems development must comply with standards. Besides the out-of-the-box metrics, knowledge libraries are available on The REUSE Company’s website:

- INCOSE Guide for Writing Requirements

- NASA’s Systems Engineering Handbook

- EARS (the Easy Approach to Requirements Syntax)

- SOPHIST

- ECSS-standards

The knowledge libraries must be used with our tools. You can also create your own set of metrics and share them as a quality library.

The quality management capability within the ecosystem of capabilities of the SES ENGINEERING Studio

SES ENGINEERING Studio is a software tool that manages the system life cycle. The tool connects and interoperates the complete ecosystem of tools involved in its concept, development, production, utilization, support, and retirement. SES ENGINEERING Studio becomes an Integration Hub. It provides full technical management support (configuration management, traceability management, conflict management, quality management, information management, knowledge management, PLE, etc.) to an extended list of connectable tools. SES ENGINEERING Studio allows smart interoperability among all the tools and complete life cycle support.

The combination of connectivity to existing tools, interoperability among them, technical management digitalization for whatever connection, ontologies, and a repository for synchronizing the sources of truth, provides a powerful system life cycle management solution with a strong REUSE approach.

The RQA – QUALITY Studio® is completely integrated inside the SES ENGINEERING Studio. It represents the quality capability of the SES environment and can be combined with the rest of the capabilities SES offers. SES ENGINEERING Studio provides a holistic and complete Digital Systems Engineering approach.