V&V Studio - verification and validation

A SMARTer way to manage the verification and validation of your engineering items and your system.

V&V Studio is a specialized product of SES ENGINEERING Studio (SES), fully devoted to verification and validation of any engineering item produced along the System Life cycle. It can either work inside SES as a capability or as a Stand-Alone product.

What is verification and validation?

Verification, validation, and quality work together. The systems engineering verification process is synthesized as “the procedures and evidence to assure that the system is developed right”. An example is whether a product or system complies with requirements, standards, etc. Validation refers to “the procedures and evidence to assure that we have developed the right system”. An example is whether a product, system, or system element meets its stakeholders’ needs and objectives.

Both concepts relate to verification and validation action as described in ISO 15288. In many cases, evidence can be provided with the help of quality management and assurance. The V&V process is applied on both sides of the V-Model. The V-Model is the graphical representation of a systems development lifecycle. The left side of the V-Model represents the definition of the project. Requirements and specifications must comply with standards, the knowledge base, or regulations. The right side of the V-Model represents the integration and testing of the subsystems and the system. The built elements must comply with the corresponding elements of the left side of the V-Model: requirements specifications, models, etc.

Throughout this V&V process, the validation against the higher abstraction levels ensures alignment with the needs and objectives of the subsystems and the overall system.

Verification and validation with V&V Studio

Using seamless evidence management, the V&V Studio provides the required tools for managing and completing the verification and validation of any work product or system.

V&V Studio offers verification and validation of:

- Requirements

- Requirements specifications

- Documents

- SysML and UML models

- Functions

- Simulations

Benefits of V&V Studio

With V&V Studio you can manage and complete the verification and validation tasks of any work product in the system.

Standard alignment and tailoring

The verification and validation processes align with the desired standard while offering the possibility of tailoring the approach selected completely.

Complete V-Model coverage

The V&V processes on the right side, and the left side of the V-Model can be prepared for, executed, and the results managed.

Time

After providing the required information and resources, V&V Studio automates time-consuming tasks such as generating the verification and validation results of the entire specification. This means that the engineer will have more time to invest in the verification and validation processes of analyzing, simulating, etc.

Money

Verification and validation processes can be applied to any engineering elements involved in the project since the kick-off. These processes reduce additional costs caused by late detection of flaws during the development of the project.

Features of V&V Studio

The most important feature of V&V Studio is the connectivity to other systems engineering tools.

Verification and validation of any engineering item

By connecting to most of the Systems Engineering software tools (IBM DOORS, Siemens Polarion, Siemens Teamcenter Requirements, DS CAMEO, IBM Rhapsody, Capella, Simulink, MS Excel, MS Word, etc.), V&V Studio can provide verification and validation evidence for any engineering item. Once the V&V Studio is installed, you can verify and validate any work product; system, system element, requirement, model, etc. These V&V items are extracted from any connection available within the V&V Studio. As long as there is a connection to the source, a V&V item can be created.

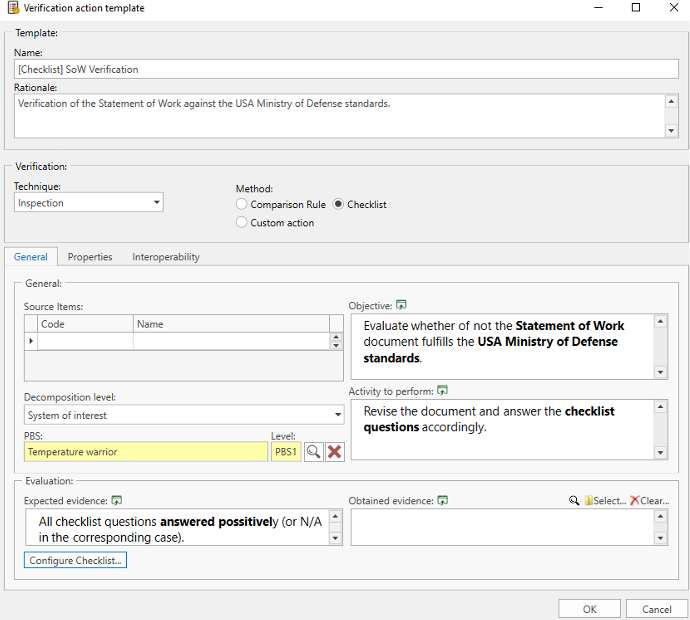

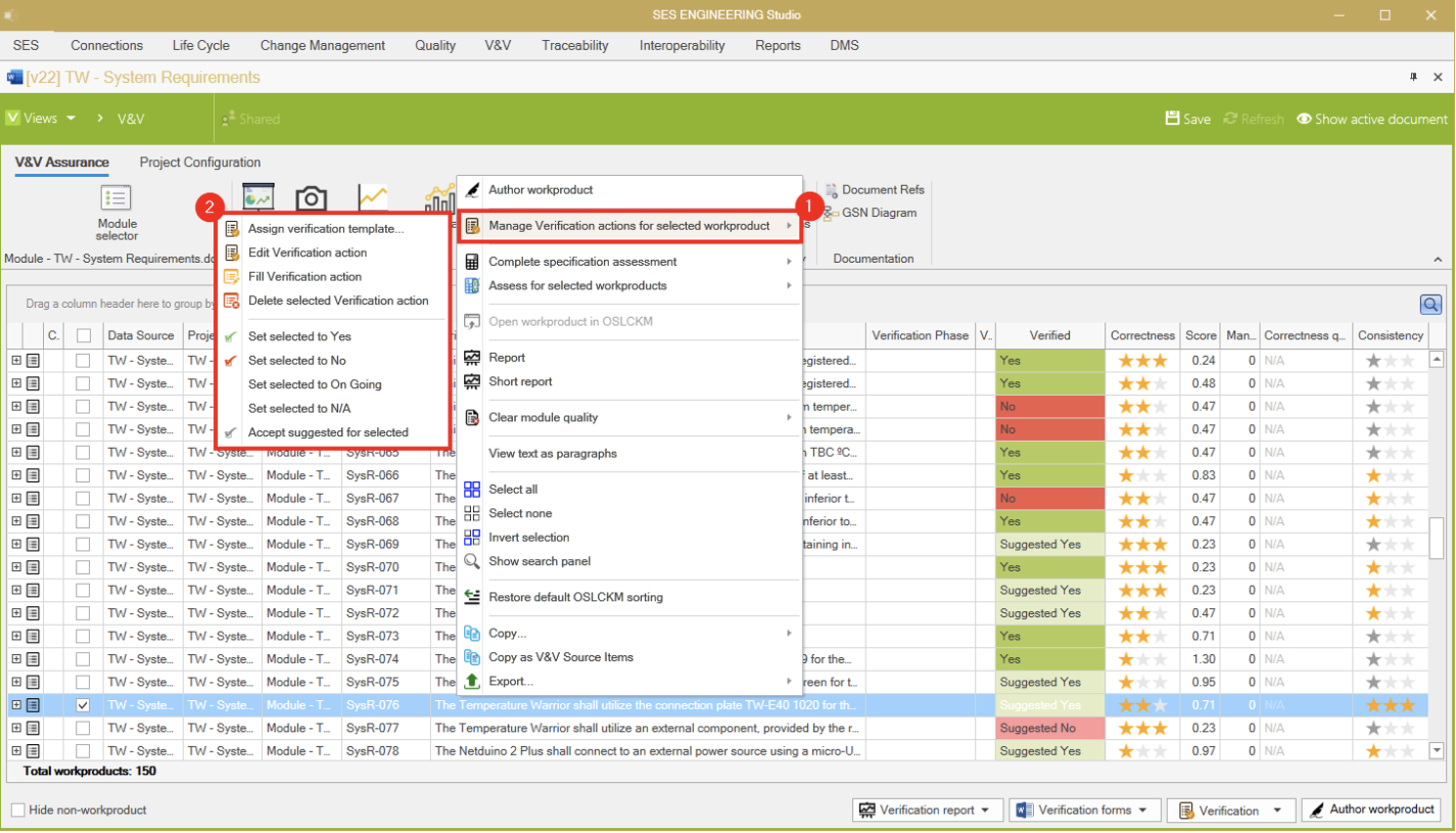

Preparing for validation and verification

Any work product is verified and validated through a set of actions. Each action is designed to allocate every piece of information (context, restrictions, technique, resource allocation, etc.) involved. A classical implementation of a verification and validation action supports a subset, including, but not limited to:

- V&V item, as the work product being assessed.

- V&V techniques to be used.

- Activity to perform.

- Expected evidence.

- Estimated time resource.

- The planned date for V&V execution.

- V&V state.

- Source items: any engineering item providing source information.

- Objectives & conditions.

- Responsible agent.

For optimization purposes, these verification and validation actions can be generated from templates. The templates can be used to define common information regarding certain processes, assign them to a set of work products, and customize them accordingly.

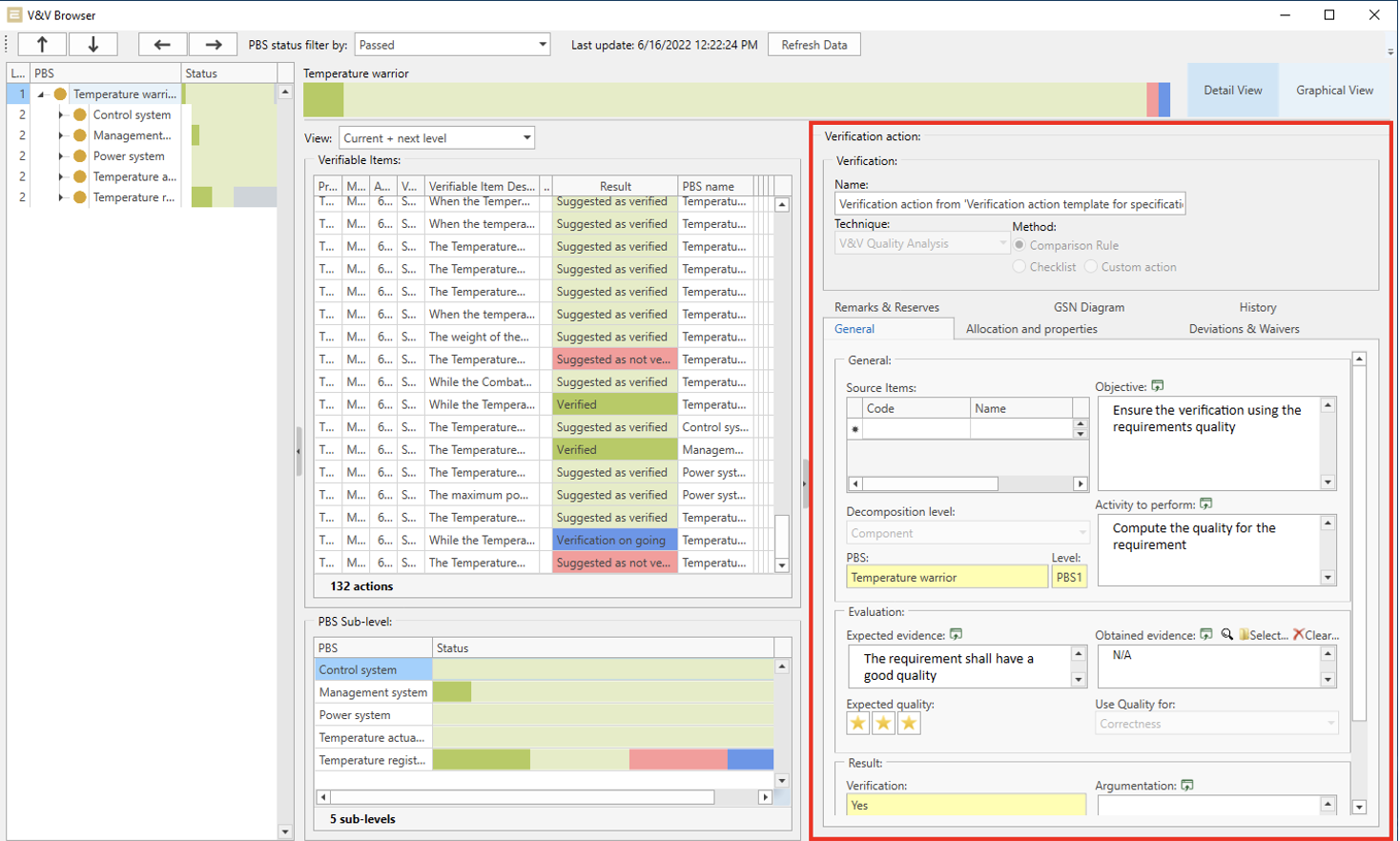

Execution of verification and validation

The different work products needed to complete the desired system are defined and built by potentially divergent organizations across the supply chain. The quality of these work products against standards is required as evidence for the V&V processes in many scenarios. Therefore, the quality must be managed and monitored throughout the system life cycle. Based upon this need, the V&V Studio reduces the interactions between OEMs and Suppliers by allowing all parties to share a common view. OEMs can define a quality certificate and share it with everyone in the supply chain. After that, the OEM can receive periodic verification reports from the supplier, digitalizing and automating the visualization of the results.

In addition, these processes are enabled by providing systems engineers with a digitalization of the attributes’ subset, including, but not limited to:

- V&V iteration.

- V&V item version.

- Actual date of V&V execution.

- Obtained evidence.

- V&V result, which can be generated automatically.

- The responsible agent for the V&V execution.

- Deviations & wavers.

- Checklists to be filled in.

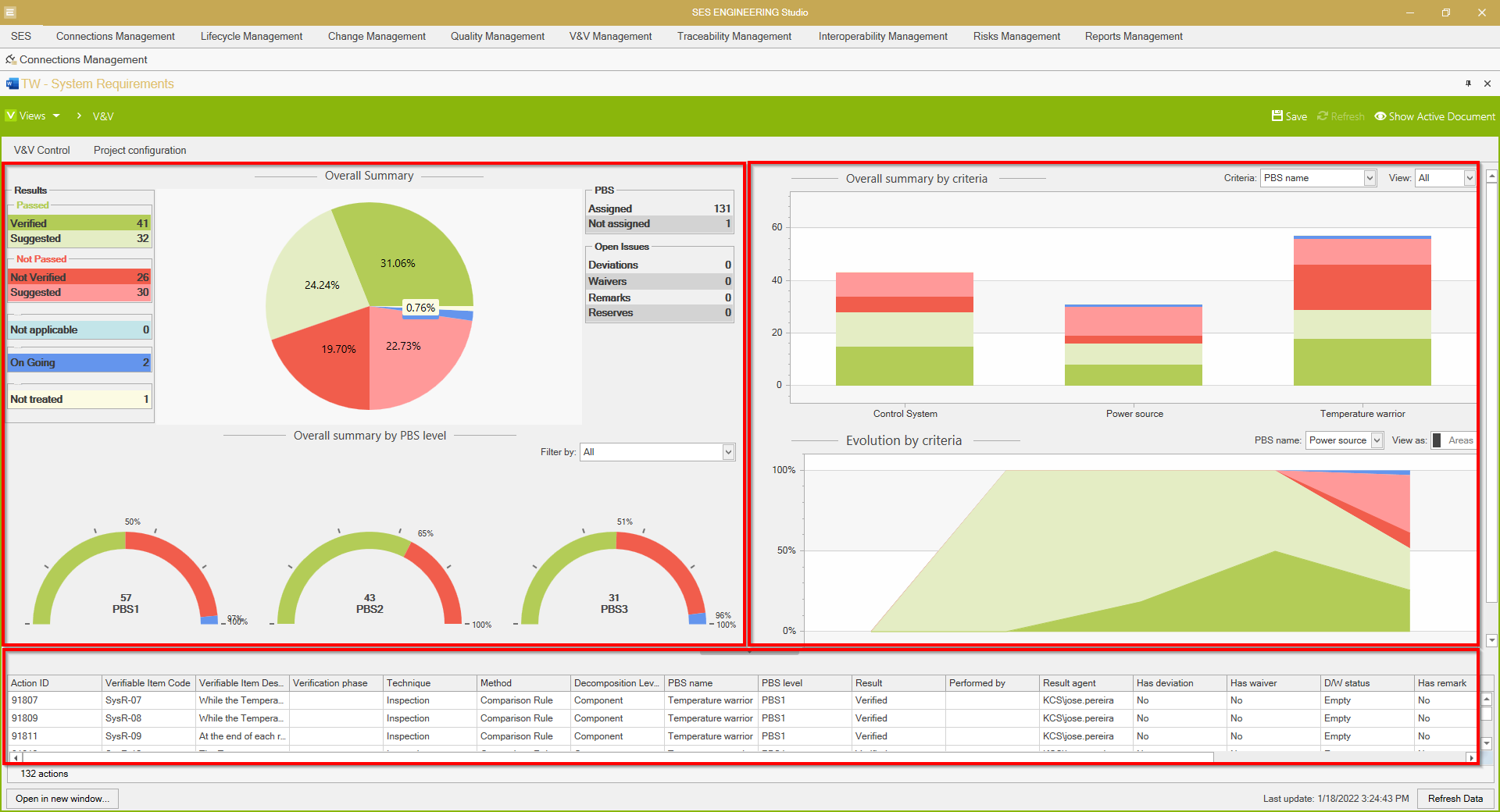

Verification and validation results management

Throughout the V&V processes, the different engineering items are continuously evolving (moving through versions). Using the V&V Studio, any systems engineer can visualize and revise the progress in real time using the evolution scoreboard. This view is included in the dashboard section, which offers a complete view of the overall status of a work product from several (customizable) perspectives.

The V&V Studio offers a browser to have a complete overall verification and validation view organized by each component. In this section, the PBS (Product Breakdown Structure) will be decomposed into all the systems, subsystems, and components, with the associated collection of V&V actions and their results.

Verification and validation with SES ENGINEERING Studio

SES ENGINEERING Studio is designed to manage the life cycle of any system by connecting and interoperating the complete ecosystem of tools. This includes the tools involved in the system’s concept, development, production, utilization, support, and retirement. SES becomes an Integration Hub and provides full technical management support to a wide list of connectable tools allowing smart interoperability among them and complete life cycle support. The combination of:

- Connectivity to existing tools

- Interoperability among them

- Technical management digitalization for whatever connection

- Ontologies

- A repository for synchronizing the sources of truth

- The possibility to define life cycle models

provides a powerful system life cycle management solution with a strong reuse approach.

The V&V Studio is completely integrated into SES ENGINEERING Studio. It represents the capability of the SES environment to provide and digitalize evidence for supporting the verification and validation processes. V&V Studio can be combined with the rest of the capabilities SES offers to provide a holistic and complete digital systems engineering approach.

50+ Connectors

The available connectors for V&V Studio are detailed in SES ENGINEERING Studio.